Change Tick Radius to change the height of the ticks.Ĭonnect joint by riveting ticks to one another. Change Tab Fraction to change the width of the ticks (tabs).Ĭonnect joint by fitting pieces together. Change Tick Radius to change the height of the ticks. Change Tick Radius to set the distance of the rivet holes from the edge of the sheet.Ĭonnect joint by fixing ticks together. Change Joint Space to set the spacing between rivets used to connect the joints. Change Hole Radius to make the holes bigger. Change Tooth Scale to set the height of the teeth.Ĭonnect joints by lacing sheets together. Change Tick Spacing to set the spacing between the cutouts. Change Tooth Radius to set the distance from the edge of the sheet for the cutouts.

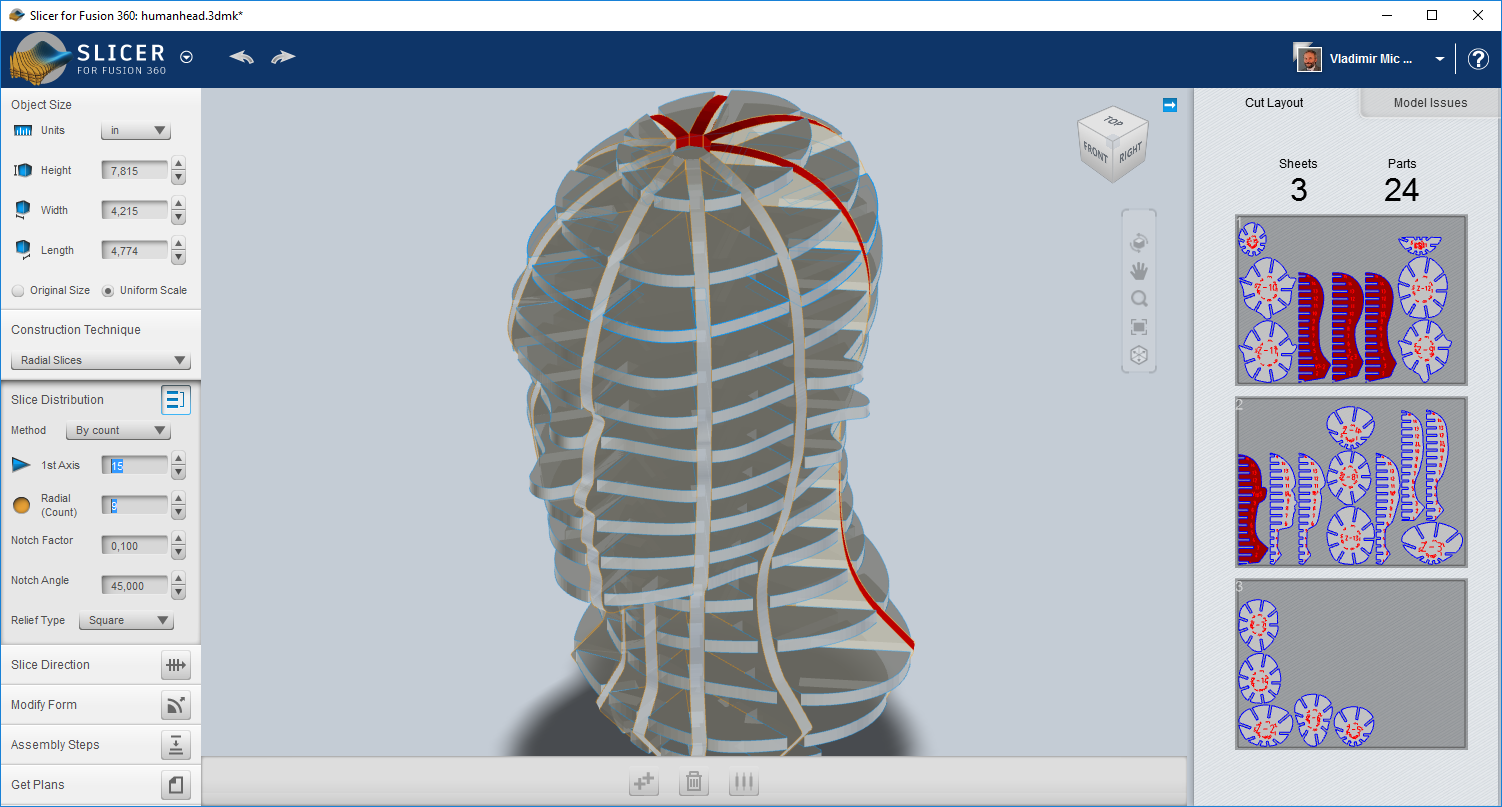

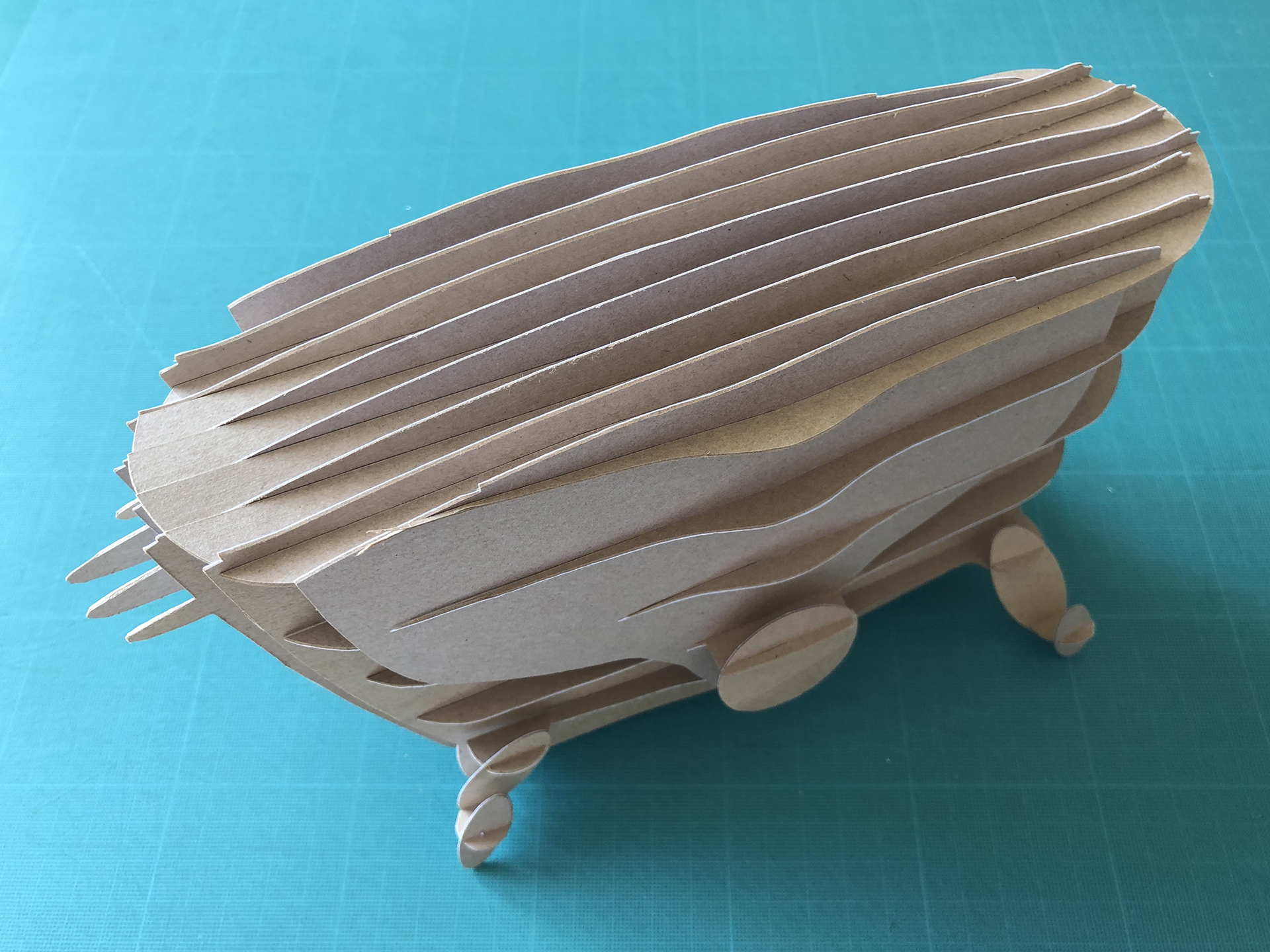

The dark areas of the image need to be cut out. Change Tick Radius to set the width of the ticks.Ĭonnect panels by folding and affixing (gluing or welding) the rectangular ticks. Joint TypesĬonnect panels by folding and affixing (gluing or welding) the triangular ticks. We are going to focus on the tab and tongue types. Same are useful for paper, others can be used for sewing or lacing. Here you can select how you want to connect your unfolded object after production. You can also split all panels for the final cut plan. If you still want to edit your model you can adjust the count of vertices in these panels or add new seams to your object. From Slicer Help (within Application) (Folded Panels) Optimize Panels/Add Remove Seams ¶ These segments (panels) are folded multiple times, then attached using one of ten different joint types. Separates your 3D model into 2D segments of triangular meshes. When you done with setting up your material choose from the Construction Techniques “Folded Panels”. You also can save some presets for your material. You can set all of these settings by pressing the little wrench and then adjusting them on the bottom of the application window. For cutting grey cardboard around 0.5 to 1.5 mm you can set this to <=1 mm. This is the amount of material the laser will take away. There is also another setting we need to take in account. This will determine how narrow/wide the holes for tongues and tabs are we are going to produce later on. What’s more important is to set the “Thickness” of your material. if your desired object size exceeds you material size the application will allow you to export several cut sheets. Another way is adjusting the size based on your material size.

You can set the “Object Size” when you need a defined size. This can be set to a fairly huge size (the laser cutter at the University of Applied Sciences Potsdam (Germany) has a size of 1200 mm to 900 mm). The manufacturing settings allow you to set the size of your material. When you import your 3D model you first need to set some options. We will cut them with different settings leaving a visual mark where to fold your material. The marks for the folding lines are enough to.

#Slicer for fusion 360 tutorial pdf

In there you’ll find the PDF under /Applications/SlicerForFusion360.app/Contents/

#Slicer for fusion 360 tutorial mac osx

Splitting the panels can save you a lot of material.Use the Right Mouse Button and paste from the pop up menu. On a German localized computer the application accepts as decimal point the comma when entering values by typing - even though the numbers are displayed with a dot.This cannot be set globally you will need to adjust this for each panel where you use units.

0 kommentar(er)

0 kommentar(er)